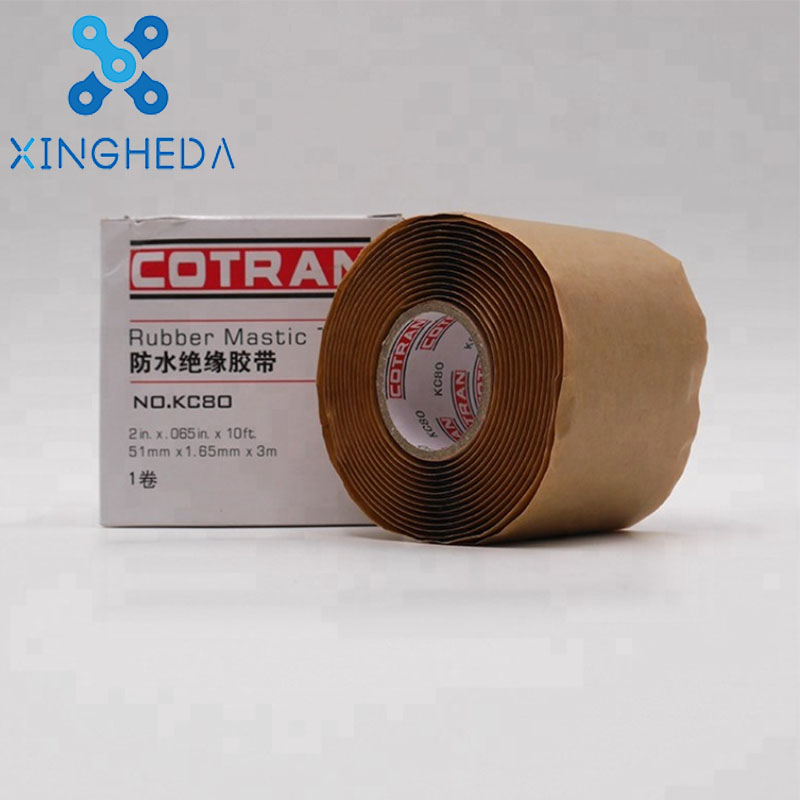

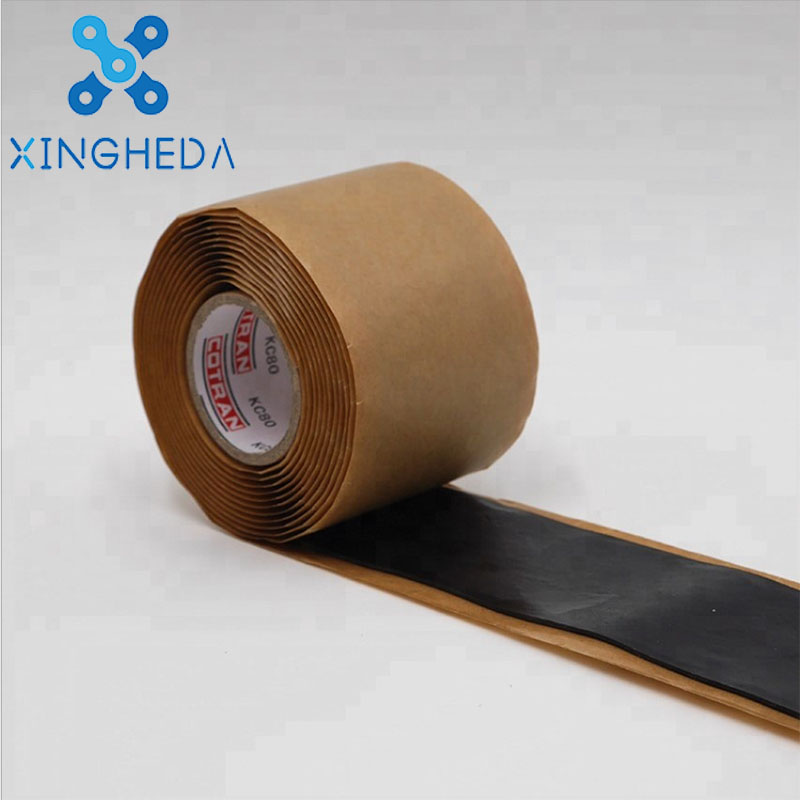

Model: KC80

Specifications: 51mmX1.65mmX3m 1 roll / box weight 0.4KG/ box

Main applications:

1. It is used for insulation, filling and sealing of all kinds of power and optical communication cable joints, withstanding voltage up to 1000 volts.

2. The connection of the bus bar is smooth and waterproof.

3, for high and low voltage electrical boxes and irregular joints inside and around the seal.

Instructions:

1, first remove impurities such as dust at the cable joint.

2. Stretch the tape to about 3/4 of the original width, so that the adhesive coating layer toward the surface of the wound cable, with an overlap rate of about 50%.

Winding:

3, the starting point and ending point of the winding should exceed 30 mm -50 mm at the edge of the joint.

|

Mechanical performance |

Typical value |

Testing method |

|

Thickness |

1.75mm |

ASTM D 4325 |

|

Tensile Strength |

1.16MPa |

ASTM D 4325 |

|

Ultimate Elongation |

850% |

ASTM D 4325 |

|

Dielectric intesity |

22.5KV/mm |

ASTM D 4325 |

|

Viscosity(PE) |

55N/50mm |

ASTM D 1000 |

|

Melting point |

A grade pass |

ASTM D 4388 |

|

Dielectric loss |

0.008 |

ASTM D 4325 |

|

Working Temperature |

90℃ |

ASTM D 4388 |

|

Emergency overload |

130℃ |

ASTM D 4388 |

|

Water absorption |

0.49% |

ASTM D 570 |

|

Water vapour percolation rate |

<0.26g/(100inch 2.24h) |

ASTM D 3833 |

|

Ozone resistance test |

pass |

ASTM D 4388 |

|

Heat exposure |

130℃ |

ASTM D 4388 |

|

UV resistance |

pass |

ASTM D 4388 |

You can contact us any way that is convenient for you. We are available 24/7 via fax, email or telephone.